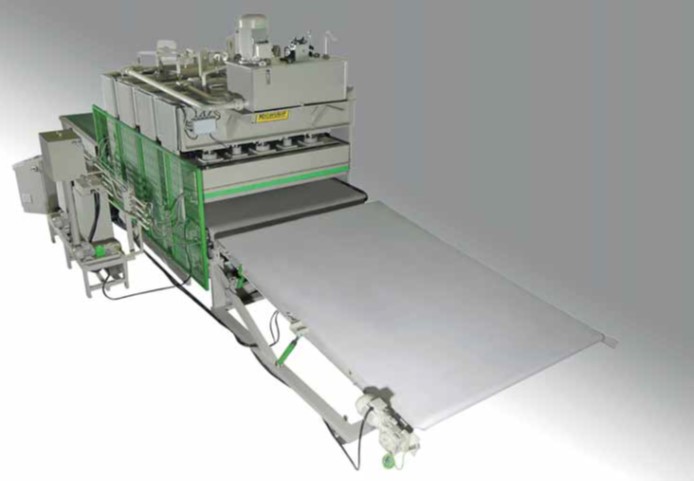

These are cold or hot platen presses with automatic loading and disloading. Automatic pressing lines are produced through the highest technology of time and they are introduced to customers after very long R&D process which includes many different tests and our experience. Finish foil, glued covering, slide, melamine, paper, P. V.C can be covered on M.D.F, plyboard or hardboard by Kocayusuf pressing lines and those covered materials can be used to produce furniture, wall, surface and door panels. In accordance with the needs of customers, pressing lines can be produced in various sizes and pressing powers, top or bottom closure types. Besides loading and disloading, if it is needed, automatic glue spreader machine, brush cleaner, automatic stowing and other applications can be integrated machines and the production capacity can be increased. Heating system is electric resistance, steam or oil typed.

Technical Features

Plate Sizes :

– Width:: mm. 1400 – 1600 – 2000 – 2250 – 2500 – 2 750

– Length: mm. 2600 – 3000 – 3500 – 4000 – 4500 – 5000 – 6000 – 7000 – 8000

– Number of Cylinders: 9-12-15 – 18- 20-21 – 24

– Pressing Power: Kg/cm2. 5 – 7 – 10-12-15 – 20-25 – 30

– Opening: 140 mm

– Plate type: Aluminium, chrome, full plate

– Heating system: thermal oil, hot water, steam, tube resistance

– Thick chrome covered mils

– Automatic pressure renewing

– Covering plates with mylar bands (optional)

-Heat resistant conveyor bands

Remote Panel Features :

– Controlling all the part of the press from the remote panel

– Digital watch tor automatic starting

– Digital thermometer for every plate

– Automatic/Manual starting mode

– Emergency stop switch (in every unite)

– Malfunction alert system

– Tube resistance heating system

– CE standards (optional)

Other heating systems (optional)

– Electrical heated oil boiler

– Steam boiler

Overview

- Category : Press Machines